coppper extraction crushing in south africa

Copper solvent extraction: Status, operating

This paper examines typical operating practice in the African Copperbelt, discusses differences compared with other parts of the world, and looks

Read More

(PDF) Copper solvent extraction: Status, operating

2016.6.20 Although the first large-scale application of copper recovery by solvent extraction took place in Zambia in the early 1970s, it

Read More

Five largest copper mines in South Africa in 2020 - Mining

Here are the five largest copper mines by production in South Africa, according to GlobalData’s mining database. 1. Palabora Mine. The Palabora Mine is a surface and

Read More

Solvent extraction in southern Africa: An update of some

2005.7.1 Southern Africa was the site of one of the first large solvent-extraction (SX) plants built, following smaller plants in the North American uranium industry and the

Read More

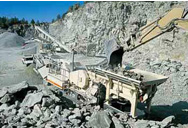

South Africa copper ore crusher exporter - LinkedIn

2023.9.11 South Africa copper ore crusher exporter. China Mining Crusher and Grinder mill Manufacturers. Unlocking South Africa's Copper Ore Potential: SBM

Read More

Unlocking South Africa's Copper Potential: Crushing Plant

2023.8.14 This revolutionizing approach to copper processing has the potential to catapult South Africa’s copper industry to new heights, creating a ripple effect of

Read More

Copper sulphate crystallization plants at remote

ProProcess Engineering (Pty) Ltd., South Africa. SYNOPSIS. The Central African Copperbelt is well known for its high-grade copper-cobalt deposits. Many hydrometallurgical copper refineries have been established in

Read More

(PDF) Copper solvent extraction: Status, operating

2014.1.1 Copper solvent extraction: Status, operating practices and challenges in the African Copper Belt. Conference: Copper Cobalt Africa, incorporating the SAIMM Eighth Base Metals Conference....

Read More

Solvent extraction in southern Africa: An update of some

2005.7.1 Southern Africa was the site of one of the first large solvent-extraction (SX) plants built, following smaller plants in the North American uranium industry and the

Read More

(PDF) Potential Processing Routes for Recovery of

2017.11.6 The resource estimates of oxidized PGM ores which are either unmined, mined, and stockpiled or discarded as overburden waste in South Africa and Zimbabwe are over 500 million tonnes.

Read More

coppper extraction crushing in south africa

كسارة تصادمية سلسلة PFW قاعدة على خبرة وفيرة من إنتاج وتسويق من كسارة تصادمية ، GM R D مؤسسة تصميم كسارة تصادمية سلسلة PFW.

Read More

Five largest copper mines in South Africa in 2020 - Mining

Here are the five largest copper mines by production in South Africa, according to GlobalData’s mining database. 1. Palabora Mine. The Palabora Mine is a surface and underground mine located in Limpopo. It is owned by HBIS Group and produced an estimated 20.822 Thousand tonnes of copper in 2020. The mine will operate until 2039.

Read More

Copper Mining and Processing: Everything you Need to Know

2014.7.17 The Basics of Copper Mining and Processing. Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using today’s compact mining equipment, copper ore is extracted from the mine. After the ore is crushed, it’s roasted, which helps to convert sulfides to oxides.

Read More

(PDF) Potential Processing Routes for Recovery of

2017.11.6 Crushing and. grinding. ... In contrast to the majority of the ores from the Bushveld Complex in South Africa, ... Cyanidation made it possible to extract 5.5% Pt and 17.3% Pd from the concentrate ...

Read More

sbm/sbm extraction machine crusher for sale.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

coppper extraction crushing in south africa

Bakerville Diamond Project South Africa XSM Crusher Copper recovery using leach/solvent extraction. Bakerville Diamond Project South Africa XSM could customize coarse crushing plants on request of each customer is demand Feed arrangement automation unreserved service cost effectiveness control are all the reasons why XSM crushers could be most

Read More

Full article: The significance of soybean production in the

2021.6.8 The manuscript addresses the importance of soybeans production in the face of the changing climates in Africa. The paper is significant to the African governments, development stakeholders, and the small-scale farmers themselves as they are the majority vulnerable members of the communities in SSA. The paper argues that from the many

Read More

Tailings - Earthworks

2023.8.18 The type of tailings dam a mining company builds is directly related to the safety of the structure. Engineers have found that tailings dams tend to be safest, i.e. most resistant to failure and collapse, when they are not built on top of or using previously-deposited tailings.However, the safest dams, like downstream dams, are more expensive

Read More

coppper extraction crushing in south africa

Coppper Extraction Crushing In South Africa Collahuasi copper mine 180km southeast of the port of iquique in northern chile ranks as the third largest copper mine in the world proven and probable copper reserves of the openpit mine as of december 2012 stood at 25895mt the mine produced t of copper in 2012 accounting for 51 of chile's total ...

Read More

coppper extraction crushing - costablanca-denia

crushing copper from its ore coppper extraction crushing dolcevita piscinebe. 02 14 32 Copper Ore Crushing Plant in Chile ore crushing and extraction equipment manufacturers in india stone crusher price solutions extract copper malachite machine sbm 4 May extraction plant crushing for copper extraction by screening protrafficin Copper Extraction Crushing

Read More

Copper Processing Multotec

Copper Processing. Copper processing uses physical, mechanical and / or chemical methods to convert run-of-mine (ROM) copper ore to high-quality, pure copper. A wide range of mineral processing equipment is used in converting the copper ore to the final copper product, our solutions range includes: Screening Solutions. Cyclone Solutions.

Read More

coppper extraction crushing in south africa

en/coppper extraction crushing in south africa.md at main 英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

en/coppper extraction crushing in south africa.md at main 英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.  Coppper extraction crushing in south africa - Manufacturer Applications copRead More

Coppper extraction crushing in south africa - Manufacturer Applications copRead More

Extraction of Platinum Group Metals IntechOpen

2018.2.21 About 80% of the worlds’ reserves for platinum group metals (PGMs) are in South Africa’s Bushveld Igneous Complex. Processing of PGM involves comminution, flotation, smelting, converting, base

Read More

Coppper Extraction Crushing - przegladbiznesu

Coppper Extraction Crushing 2019-05-03T18:05:12+00:00 coppper extraction crushing. Extraction of copper from copper sulfide minerals by roasting and smelting, a tutorial suitable for Crushing : mined copper ore is crushed into very small pieces Copper Extraction Metals Chemistry YouTube 10 Mar 2020 The total process, these steps, mining, milling,

Read More

Transparency on greenhouse gas emissions from mining to enable ... - Nature

2020.2.3 For instance, degradation of carbonate minerals has been estimated to contribute almost 8% to GHG emissions at BHP Billiton’s Olympic Dam copper–uranium–gold–silver mine in South Australia 6.

Read More

coppper extraction crushing in south africa

separation titanium ore in south africa Copper Ore Crushercopper crushing machinery in south africa. separation titanium ore in south africa XSM could customize coarse crushing plants on request of each customer is demand Feed arrangement automation unreserved service cost effectiveness control are all the reasons why XSM crushers could be most

Read More

coppper extraction crushing - centre-de-pediatrie

Extraction of Copper . The main process lies in extracting the copper from the ore. It comes in various steps. Almost 90 percent of the copper can be mined through the process of extraction. Crushing and Grinding . When the copper has made its way to extraction form the mines, the ores coming from the mine contains almost about 2 percent copper.

Read More

Biodiesel: Production, Characterization, Metallic Corrosion

2012.12.3 The use of vegetable oil as an alternative renewable fuel to compete with diesel oil was proposed in the early 1980. The more advanced study with the sunflower oil happened in South Africa because of diesel oil embargo, and the first International Conference on Plants and Vegetable Oils was held in Fargo, North Dakota, in August 1982 .

Read More

(PDF) Mining the Katanga (DRC) Copperbelt: geological

2011.1.1 In 2009, we documented high exposure to cobalt and other trace elements in people living within 3 km of industrial mines or smelting operations 14 .

Read More

(PDF) The environmental impacts of copper production in

2019.12.20 Historical rates of copper extraction by geographical region 1970-2017 Millions of tonnes Top 10 producers of copper ore income group, 1990-2010 Top 10 producers of refined copper income group ...

Read More

ppper extraction crushing in south africa

ppper extraction crushing in south africa 2020-04-27T01:04:25+00:00; coppper extraction crushing aircraftenginecz coppper extraction crushing in south africa coppper extraction crushing in south africa Extraction of gold from mined rock accomplished by agitation in a cyanide solution Elemental metal commodity (eg iron, copper, lead, zinc, tin, or nickel)

Read More

Pretreatment of South African sugarcane bagasse using a

2018.9.11 Background Sugarcane bagasse is an abundant and geographically widespread agro-industrial residue with high carbohydrate content, making it a strong candidate feedstock for the bio-based economy. This study examines the use of the low-cost protic ionic liquid triethylammonium hydrogen sulfate ([TEA][HSO4]) to fractionate a

Read More

Coppper Extraction Crushing In South Africa

Jan 18, 2021 copper extraction crushing in south africa coppper extraction crushing in south africa coppper extraction crushing in south africa As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds ...

Read More

Extraction of vanadium from titanoferrous magnetite

2021.1.1 Many of the V-bearing titanoferrous magnetite ores outside of China are richer than the Chinese ones, such as South Africa’s Bushveld raw ore with a V 2 O 5 content of 1.8% and Finland’s Otamatti raw ore with a V 2 O 5 content of 0.4%. Stable deposits exist, such as those in Catchikara, Russia, and Bushveld, South Africa. 4.4.1.

Read More

Moving towards deep underground mineral resources

2023.1.1 South Africa: Driefontein 5 shaft Gold Mine: More than 3.4 km below surface. South Africa: Kusasalethu Gold Mine: More than 3.276 km below surface. South Africa: Moab Khotsong Gold Mine: From 2.60 km to 3.05 km below surface. South Africa: South Deep Gold Mine: Down to 2.995 km below surface. South Africa: Kidd Creek

Read More

coppper extraction crushing in south africa

coppper extraction crushing in south africa إنشاءات الكسارات والطحن والتعدين كسارة فكية سلسلة PE كسارة فكية سلسلة PEW الفك كسارة HJ سلسلة كسارة تصادمية سلسلة PF كسارة تصادمية سلسلة PFW ...

Read More

An Overview of Nickel Utilization from Laterite Ore

2023.1.19 A limonitic laterite ore (TFe 50.88 wt% and NiO 0.38 wt%) was reduced at 700 ℃ in the gas of 30 vol.% CO/ (CO + CO 2) for 90 min. The leaching percentage of nickel in the reduction product was 93% after leaching using 0.05 mol/L H 2 SO 4 at temperature of 70 ℃ for 60 min [ 65 ].

Read More

Mining And Refining: Copper, The Metal That Built Technology

2022.1.10 The world’s most productive copper mine right now is the Minera Escondida in the Atacama Desert in Chile, which produced $10 billion worth of copper in 2007 and can output 1.2 million tons a ...

Read More

The impact of mineral resource extraction on ... - ScienceDirect

2022.6.1 The impact of mineral resource extraction on communities: How the vulnerable are harmed. Author links open overlay panel Dou Shiquan a, Franklin Amuakwa-Mensah b d, Xu Deyi a, Chen Yue a, Cheng Yue c. ... The forgotten resource curse: south Africa's poor experience with mineral extraction. Resour. Policy, 38 (2013), pp. 549-557,

Read More

Copper Ore - an overview ScienceDirect Topics

Copper ore usually contains about 0.5 to 2% copper that occurs in the form of disseminated and stringers. The run of mine ore is reduced from 150 mm to 25 mm size in Jaw and Cone crushers. The crushed ore is grinded in ball mills to −74 μm size. The ore is processed by froth flotation comprising rougher and scavenger cells.

Read More

- مخروط محطم الزئبق ميكا

- مصنع تضميد خام الذهب

- ورق جریان سنگ زنی سنگ معدن در

- مطحنة الكرة إجراءات العمل الآمن مطحنة الكرة

- همراه حمل و نقل سنگ شکن

- الصب مسبك أمبير تأثير محطم شريط ضربة في الإمارات العربية المتحدة

- scm 8021 آسیاب فوق العاده نازک

- طاحونة غير مركز لقطع صغيرة

- مطحنة ختم للبيع في السودان

- الحجر الجيري في صناعة الإسمنت

- طاحون الشر الجزء الثاني hd

- محطم المصنعين قطع الغيار في أوروبا

- محطم PEX 250 X 750

- مخروط كسارات النحاس تعدين خام

- كتل الخرسانة ماكينة للبيع في تكساس